Here's where things went horribly wrong. The aux battery and DC/DC board mounts to the battery box via threaded studs and 1/2" long 1/4" bolts. Unfortunately the holes were all the wrong size and the studs were not installed at the factory, as the instructions assume. It took me a while to figure out the right stud to use, drill out the holes, install the studs, then moved forward.

Since I'm bolting a weatherproof enclosure into this area, I had to drill holes slightly below stock. I also had to clean up the plastic welding bead on the inside joint. I melted it with my soldering gun, then scraped away the excess while it was still warm.

Another big problem with the directions is it assumes a certain DC/DC model with bolt terminals on the top, not with a cable coming out the top like mine. Reading ahead I see I'll have to double-lug some of the spade lugs to work around this problem, but I'm getting very flexible and creative now.

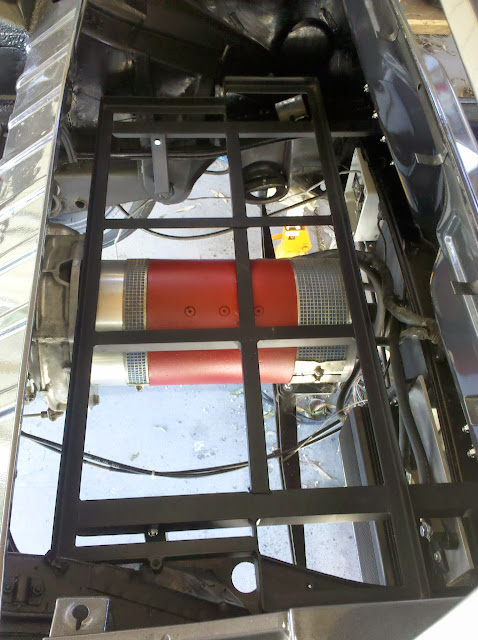

And finally here is the relay board in its enclosure, ready to have wires run into it. I'll dummy everything up and figure out how best to run the wires into the box using probably three gland nuts.

This is the aux battery mounting area. I'll have to pick up a battery tomorrow to be able to continue cutting and mounting the rest of the cables. For the record, it's a U-1 style 12V battery, maximum size 7 3/4" L x 5 3/16" W x 7 5/16" H, with 1/4" bolt-on terminals.

Well that was the end of a long, hot week. I think I need a break from the project for a while!