My kit came with a large, single unit Zivan charger that won't bolt vertically to the area shown in the directions. With some Google image searching, I found other EA kit people with the same unit and recognized the L-shaped mounting bracket that is left in my getting-very-small parts pile. I bolted it into place.

Here is the charger bolted on the bracket. I had to drill drill four mounting holes in the bottom of the plate.

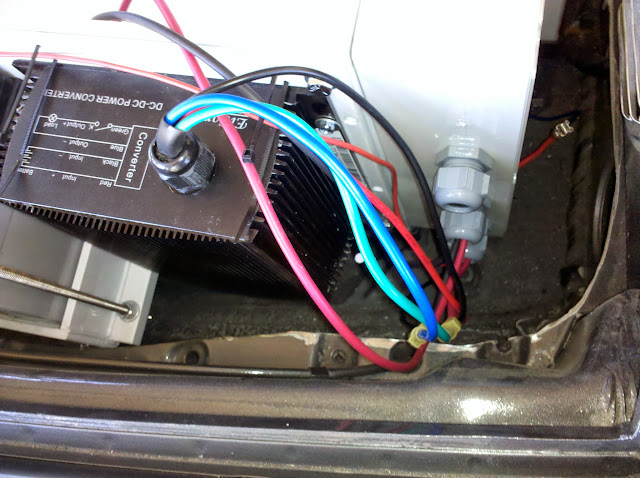

And here it is in place in the car.

This is the Anderson connector that ties the charger's high-current DC output to the battery string. I drilled a hole in the side of the bracket and put the two conductors through a grommet. This will allow for better wire management as the charger bracket pivots up. Unfortunately EA instructions to make the red conductor back to the Battery + post still ended up about 8" too short, so I had to re-make that to the proper length.

All I have left here is to run the AC input cable around the edge and into the wiring box.